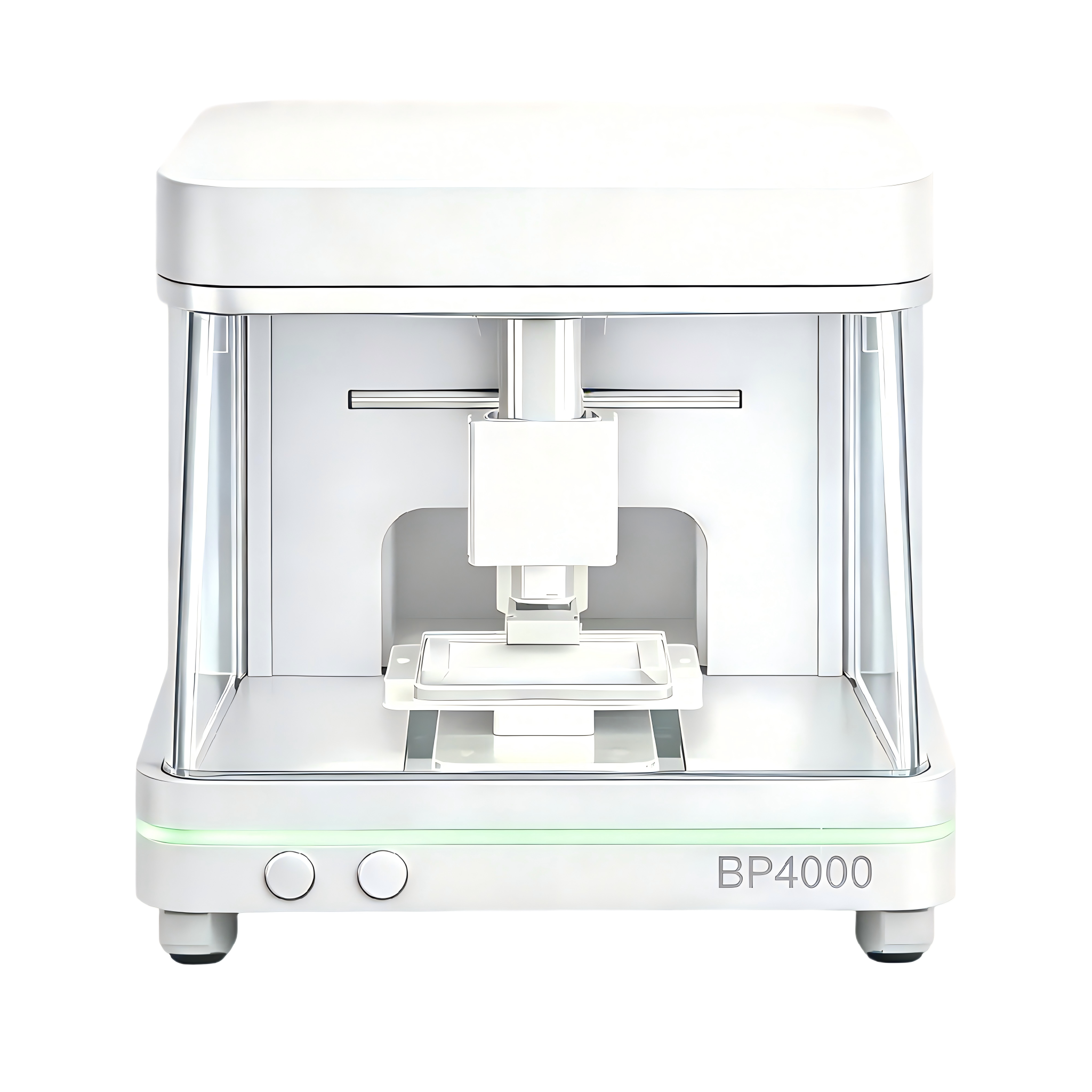

The automated organoid biofabricator BP4000 leverages high-throughput microdroplet generation and low-shear-force manipulation to precisely control cell seeding density and spatial distribution while maintaining high cell viability, thereby laying the foundation for standardized construction of three-dimensional models.

u High-precision printing mode enables the generation of standardized organoids with uniform size, ensuring batch-to-batch reproducibility;

u Incremental printing mode improves sample utilization efficiency and is well suited for small-volume samples;

u The Optical-assisted printing mode provides visual guidance for precise positioning in immune cell–organoid co-culture models, improving both inter- and intra-experimental consistency.

In addition, the system employs a gel–liquid interface culture mode (GLI) , which allows organoid recovery and downstream characterization without the need to dissolve the hydrogel matrix. This approach not only simplifies experimental procedures but also improves overall organoid quality.

| Supported substrate materials | OK |

| Spot array | pattern |

| Aperture uniformity | Cell particle size / Cell count CV < 15% @ High-Precision Mode;Cell count CV < 15% @ Incremental Mode |

| Cell survival rate | >90% |

| Compatible consumables | 24-well/96-well/MIMICup perfusion system |

| Full plate preparation | Automated liquid handling |

| Base plate temperature control (optional) | Room temperature - 40℃ |

| Sample pool temperature control (optional) | 2-8℃ |

| Sterile solution (optional) | Built-in UV sterilization lamp, additional custom ultra-clean bench/safety cabinet required |

| Emergency stop (optional) | Emergency stop switch |